Purpose - Preparation for filling and filling keg-barrels with beer, kvass, wine, drinks (with a flat fitting)

Control mode - Automatic

Capacity - up to 30 KEG/h

Purpose of function

Cleaning and filling kegs (with flat fitting) with beer or kvass (mild rye beer); production capacity – up to 30 kegs/h.Operation mode

Automatic.Picture of the Unit

|

|

|

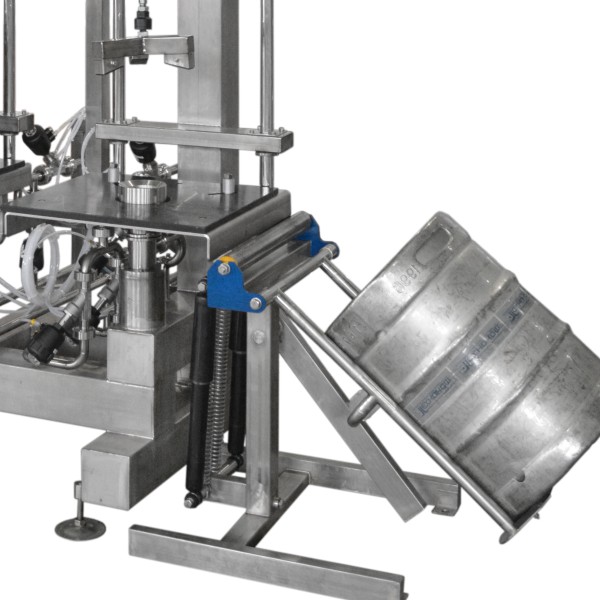

Picture of a Keg-Tilter (optional device)

|

|

|

Operation cycle sequence (position #1)

- Rinsing with hot water;

- Blowing-off with compressed air;

- Heat-up and cleaning with hot lye solution;

- Blowing-off with compressed air;

- Rinsing with hot water;

- Blowing-off with compressed air;

- Heat-up and cleaning with hot acid solution;

- Blowing-off with compressed air;

- Rinsing with hot water;

- Blowing-off with compressed air;

- Rinsing with cold water;

- Blowing-off with compressed air;

- Sterilization with steam;

- Blowing-off with CO2 (if required);

- Notching with CO2 (if required).

Operation cycle sequence (position #2)

- Blowing-off with CO2;

- Notching with CO2;

- Filling with product.

Video of the Unit in production

Unit configuration

The factory-assembled unit is mounted on a skid and comprises the following parts and blocks:- working bench with pneumatic clampers for kegs fixing;

- tanks heating elements for storage of lye and acid cleaning solutions;

- circulation pumps;

- electric switch cabinet, with PLC (by “OVEN-K”); operator’s touch-screen panel and pneumatic devices (by “SMC”);

- temperature and level transmitters;

- pipe connections, with valves, couplings and fittings.

Key technical features

|

Parameter Units |

Value |

|---|---|

|

Production capacity (for kegs of 50L format), pcs/h |

up to 30 |

|

Number of working stations (heads position), pcs |

2 |

|

Hot water flow consumption (at pressure 3kg/cm2), max m3/h |

0.3 |

|

Cold water flow consumption (at pressure 3kg/cm2), max m3/h |

0.2 |

|

Steam water flow consumption (at pressure 3kg/cm2), max kg/h |

5 |

|

Compressed air consumption for pneumatic system (required compressed air purity as per GOST 17433, at pressure 6 kg/cm2), max m3/h |

1.5 |

| Compressed air consumption for kegs blowing-off (required compressed air purity as per GOST 17433, at pressure 2.5 kg/cm2), max m3/h | 2.0 |

|

CO2 consumption (at pressure 2 kg/cm2), max m3/h |

5 |

| Tank* capacity for lye cleaning solution**, max L | 140 |

|

Tank* capacity for acid cleaning solution**, max L |

140 |

|

Basic material of construction |

stainless steel AISI-304 (08Х18Н10) |

|

Ingress protection rate of switch cabinet |

IP 54 |

|

Total installed capacity, kW |

12.0 |

|

Power supply voltage, V |

380 |

|

Dimensions of the Unit, mm |

1510х1410х2200 |

|

Weight of the Unit, max kg |

440 |

Concentration of acid cleaning solution must not exceed 1.5%.

** - the tanks are not intended for dilution of concentrated lye or acid solutions.

Standard delivery terms

Scope of services:- Manufacturing of the Unit;

- Start-up and commissioning at the Customer’s site, with training course for the staff – by additional agreement with the Customer.

- Technical passport and manual;

- Declaration of correspondence to requirements of the Technical Regulations of the Customs Union (TRCU).

Guaranteed operating lifetime – 12 months.

IF YOU HAVE QUESTIONS, SET THEM TO US!